|

| A crossing in synthetic weaving. The continuous scaffold strand (orange) visits the entire fabric but makes none of the crossings. Short staples (purple and white) specialize in making the crossings. |

|

| The same synthetic weave crossing as seen from the 'wrong' side of the fabric showing the tag ends of the white staples. |

Weaving is perhaps our most useful technique for constructing a fabric surface, but it can be unwieldy at large scale. How would you weave a building? If you've ever woven a basket, imagine manipulating a thicket of free ends some meters in length.

|

| Unit weaving, Da Vinci style. |

|

| Unit weaving, IQ's style. |

|

| Unit weaving,Twogs style. |

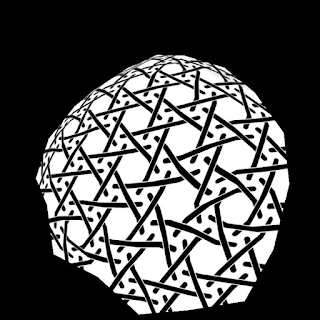

One solution is

unit weaving (nexorades etc.) This is an idea that dates back to Leonardo Da Vinci. Unit weaving solves the problem of scale by weaving very short elements-- basically splices are placed everywhere. The structural weakness of the splices limits the practical application of this approach.

|

| Pre-formed wire crochet. |

Pre-formed wire crochet builds a surface from a continuous unspliced wire. The wire's path is loopy which makes it difficult to produce and maintain a precise surface geometry. One special advantage of pre-formed wire crochet is that information the crocheter needs in order to build the surface can be carried in the pre-bending of the wire.

|

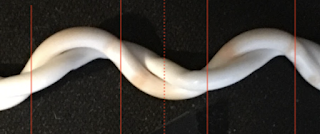

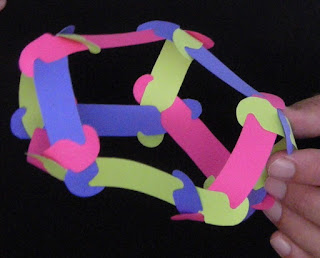

| Synthetic weaving. |

Synthetic weaving is hybrid unit-weaving and pre-formed wire crochet that derives from mathematical insights into basket weaving, experience with unit weaving, and the

scaffold-strand technique being used at Karolinska Institutet in Sweden to self-assemble nanoscale baskets from molecules of DNA.

I use

synthetic in the sense of "put together." Even though a single long wire, the

scaffold strand, constructs the entire surface (as in crochet) it fails to make any of the necessary weave crossings! That work is left to specialists: short helical unit weavers called

staples. In some cases these staples can all be identical, interchangeable, and reuseable. The pre-bent scaffold strand carries complete geometric and working-order information for the weaving. While the scaffold strand does not participate in any of the crossings, it does contribute to the strength of the bond between the two helical strands that wrap around it.

Synthetic weaving is like unit weaving but with very strong splices where all the build information is in a pre-bent wire, and like pre-formed wire crochet but with the straight-line force transfer of weaving.